Tire benchmarking to save your fleet money

Jun 14, 2022

Tire benchmarking to save your fleet money

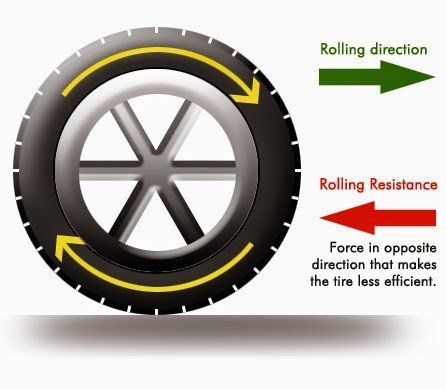

It is no secret that owning and operating any kind of vehicle fleet is expensive. Even after the initial purchase of the fleet vehicles, there will be never ending expenses incurred such as maintenance, replacement of wear items such as tires, and of course fuel costs. With the current economic conditions fleet operators are looking for every opportunity to save money within day-to-day expenses. One very important aspect to consider which involves one of the largest expenses, fuel consumption, is the efficiency of the tires installed on the vehicle. Believe it or not, rolling resistance impacts fuel consumption greatly. According to the Alternative Fuels Data Center, in passenger type vehicles approximately 4-11% of the fuel consumed is being used to overcome the tires rolling resistance. Now looking at larger vehicles such as semi-trucks, box trucks, and heavy-duty work/haul trucks, this percentage of fuel consumption can be as much as 33%. This means that for every 10% lower rolling resistance, increases the vehicles fuel economy by approximately 3%. With the average semi- truck getting 6.5 MPG and the current national average cost of diesel at $5.75 a gallon, choosing a lower rolling resistance tire could save an astounding amount of money over time.

Standards Testing Labs can test to industry standard rolling resistance tests such as ISO 28580 and SAE J1269. When selecting the tire supplier for your fleet, a benchmark study can be run on several tire options. This would require one of each tire that is in consideration for the fleet to be tested to the same specification, then reviewing and analyzing the data to compare the rolling resistance values. This is a non-destructive test that would allow the tires to be installed on a fleet vehicle. This means that the only expense incurred to the customer is the cost of testing, and the initial purchase of the tires that can still be used after testing is complete. Benchmarking tires is a process utilized by many large fleet operations to help lower incurred expenses. Endurance testing is another common benchmark test to assess the lifespan of a tire. This process requires one of each tire to be run to the DOT endurance test specifications, once it is verified the tire has met the minimum requirements, testing continues increasing the load in steps until the tires fails. This type of test is destructive, and the tires are no longer useful after testing, but allows the customer to make the most educated decision comparing the initial cost of the tires to the estimated life of the tire. Selecting a tire with a more durable construction will not only lengthen the life of the tire, but also avoid potential damage to vehicles due to premature blowouts, and costly roadside repairs.

When it comes down to analyzing fleet costs and proactively making decision to save money in day-to-day operations, the physical testing of components such as tires can be extremely beneficial to fleet operators and help to create a better overall efficiency.

If you, or your company is interested in learning more about STL and, the services we provide, do not hesitate to explore our website and/or contact us via our online submission form. You can also contact us directly at (330)-833-8548 or corporate@stllabs.com

Machinery/TTI

Standards Testing Labs

1845 Harsh Avenue S.E.

Massillon, OH 44646

Tire & Wheel Testing

Smithers

1845 Harsh Avenue S.E.

Massillon, OH 44646

Toll Free: (800) 833-8547

Main Office: (330) 833-8548

Fax: (330) 833-7902

Contact Us

We will get back to you as soon as possible.

Please try again later.

Contact Us

We will get back to you as soon as possible.

Please try again later.

All Rights Reserved | Standards Testing Labs

All Rights Reserved | Standards Testing Labs