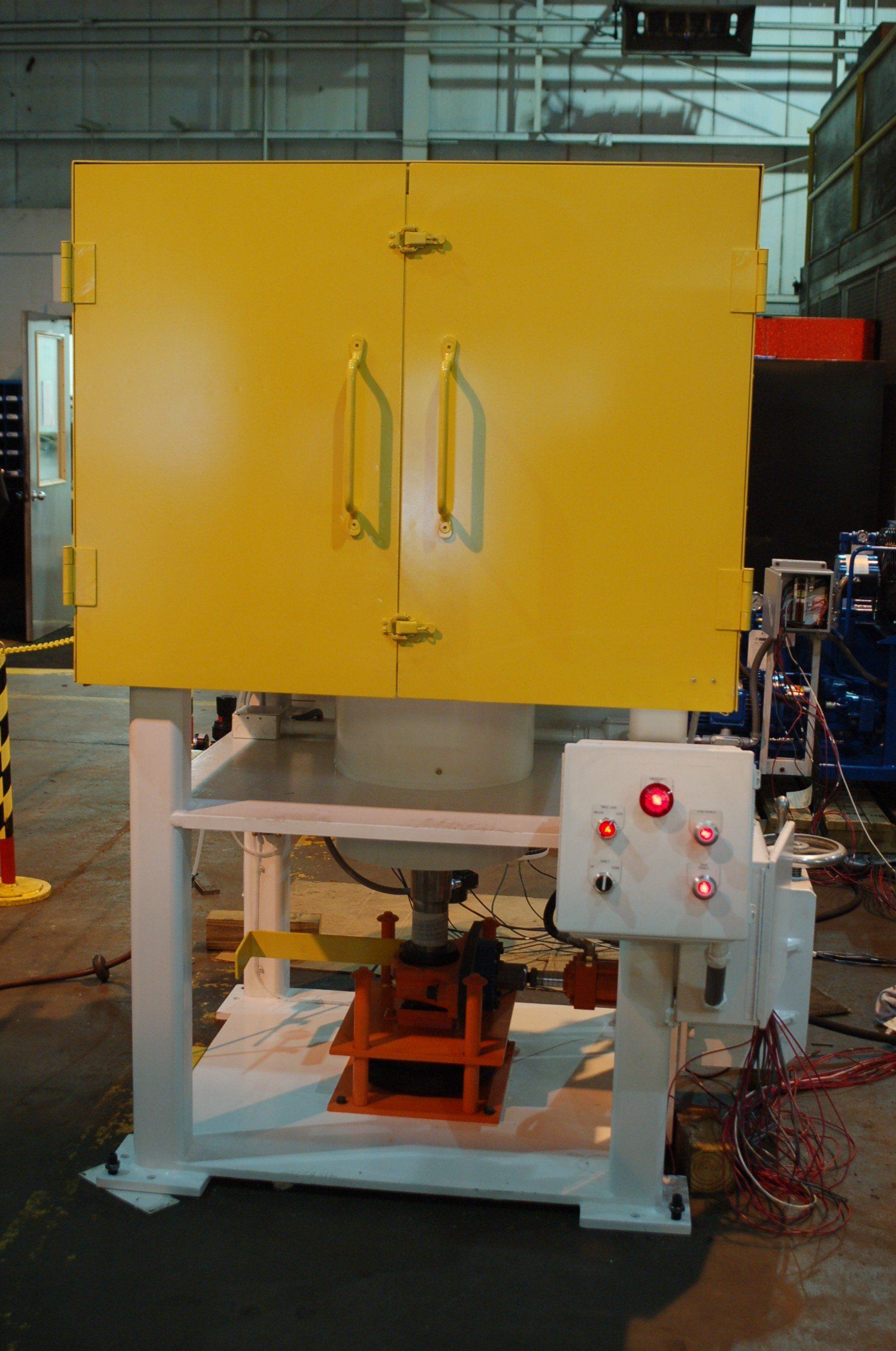

Rotary Fatigue Test Machine

Standards Testing Laboratories’ Rotary Fatigue Wheel Test Machine is a proven workhorse for testing wheels worldwide. This machine simulates the forces applied to the wheel when cornering during rotation. These machines are designed to customer specifications and can be manufactured to accommodate varying test product sizes through a range of specifications.

Features:

- PLC or PC (Allen Bradley / National Instruments) Control system

- Operator interface panel (touch screen)

- Hydraulic or electromechanical loading with self-contained power unit.

- Airbag shaft lift system for wheel mounting

- Cylinder leveling system for ensuring 90-degree force application

- Table lock for ease of torquing wheel

Capabilities:

- Capable of testing wheel diameters from 12-30 inches

- Programmable control system for testing

- Automatic shutdown for loss of load, deflections exceeding set point or preset test cycles, and time

Specifications: (standard machine)

- Speed: 100 to 800 RPM

- Max load: 50,000 ft-lbs (222kN)

- Table diameter: 40 inches

Optional:

- Addition of slip rings for strain gauge connection